Introduction:

In the ever-evolving landscape of label technology, one category stands out for its exceptional durability – self-laminating labels. These labels have earned their reputation for resilience and longevity, and in this blog post, we'll dissect the key factors that contribute to their unmatched durability.

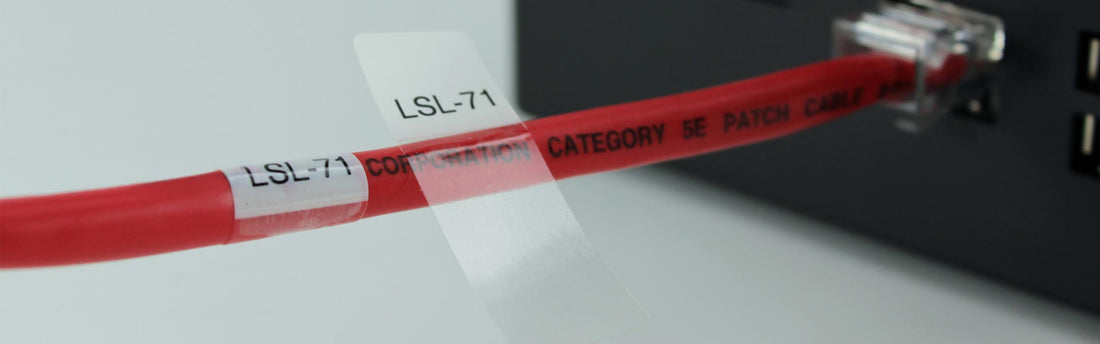

Layered Protection:

Self-laminating labels are designed with a protective layer that shields the printed information from external factors. The unique construction involves a transparent laminate layer that encapsulates the label, forming a robust barrier against moisture, chemicals, and physical abrasions. This layered protection ensures that vital information remains intact, irrespective of the challenges it faces.

Waterproof and Weather-Resistant:

Traditional labels often fall victim to water damage and weather-related wear and tear, compromising their effectiveness. Self-laminating labels, on the other hand, are engineered to be waterproof and weather-resistant. The laminated layer acts as a shield, preventing water infiltration and safeguarding the label against the adverse effects of varying environmental conditions.

Chemical Resistance:

In industrial settings where labels may come into contact with a variety of chemicals, self-laminating labels excel. The laminate layer provides a chemical-resistant barrier, ensuring that the printed information remains legible and unaffected by potentially corrosive substances. This resistance to chemicals is a key factor contributing to the prolonged life of self-laminating labels.

UV Stability:

Exposure to ultraviolet (UV) rays can cause labels to fade, peel, or deteriorate over time. Self-laminating labels, however, exhibit remarkable UV stability. The transparent laminate layer acts as a shield against the harmful effects of sunlight, preserving the integrity of the label and its printed content even when exposed to prolonged periods of UV radiation.

Temperature Endurance:

Extreme temperatures can pose a challenge for many labels, leading to adhesion issues or material degradation. Self-laminating labels are engineered to withstand a broad range of temperatures, maintaining their adhesive properties and structural integrity in both hot and cold environments. This temperature endurance further contributes to their exceptional durability.

High-Quality Materials:

The durability of self-laminating labels is rooted in the use of high-quality materials. The combination of a sturdy base material for the label itself and a transparent laminate layer crafted from durable polymers ensures a robust final product. These materials are carefully selected to withstand the rigors of various environments, making self-laminating labels a reliable choice for diverse applications.

Conclusion:

In the world of labels, self-laminating labels stand as a testament to durability, thanks to their layered protection, waterproof and weather-resistant properties, chemical resistance, UV stability, temperature endurance, and the use of high-quality materials. Businesses seeking labels that endure the test of time and environmental challenges find a dependable ally in self-laminating labels. As we navigate the demands of modern labeling, the enduring strength of self-laminating labels becomes not just a feature but a strategic advantage for those who prioritize longevity and reliability.